Injection molding machine

For the production of high-precision plastic products, injection molding machine to electric development. Electric injection molding machine than the previous hydraulic injection molding machine is more environmentally friendly and more energy saving, in the era of environmental protection, its demand has been increasing.

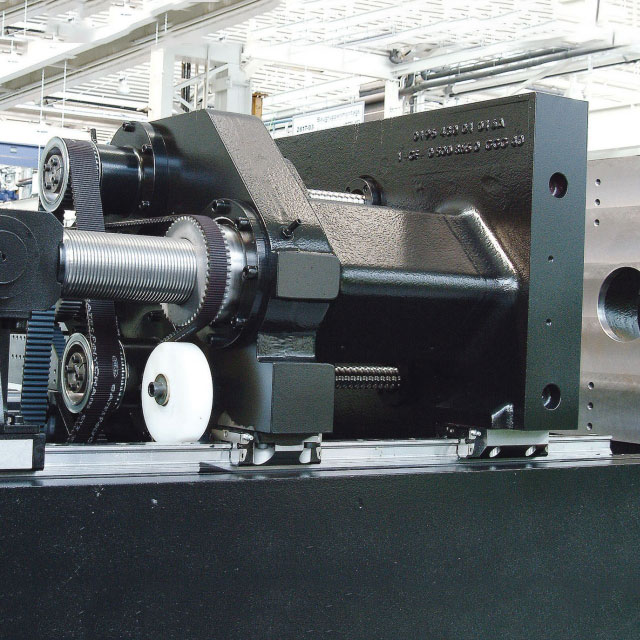

With this electricization, the parts are expected to maintain high reliability under unprecedentedly harsh working conditions.SEOR high load capacity products, is the mechanical drive (injection shaft, clamping shaft, ejector shaft, extrusion shaft, plasticizer) an indispensable important part.

SEOR products include plastic injection molding machine used, by optimizing the loop configuration to ball diameter limit and special ball groove design measures such as high load, greatly improves the load resistance of high load special ball screw drive ", as well as the special ball screw driven by high bearing load of large diameter ball, realized the high load capacity of thrust angular contact ball bearing and high load capacity, high rigidity SEOR cutting-edge technology and environmental protection products "roller guide".

As one of the few integrated manufacturers in the world that can fully develop and provide mechanical components, SEOR is committed to contribute to the future development of injection molding machines.